903-509-2256

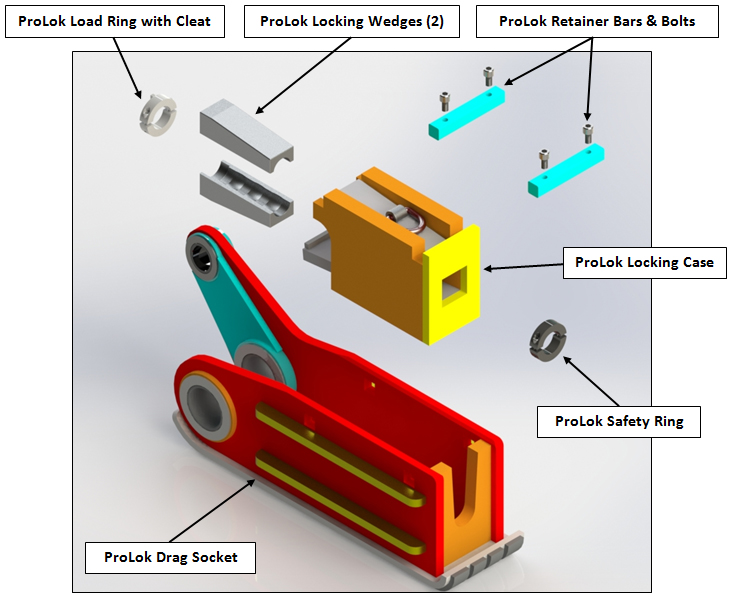

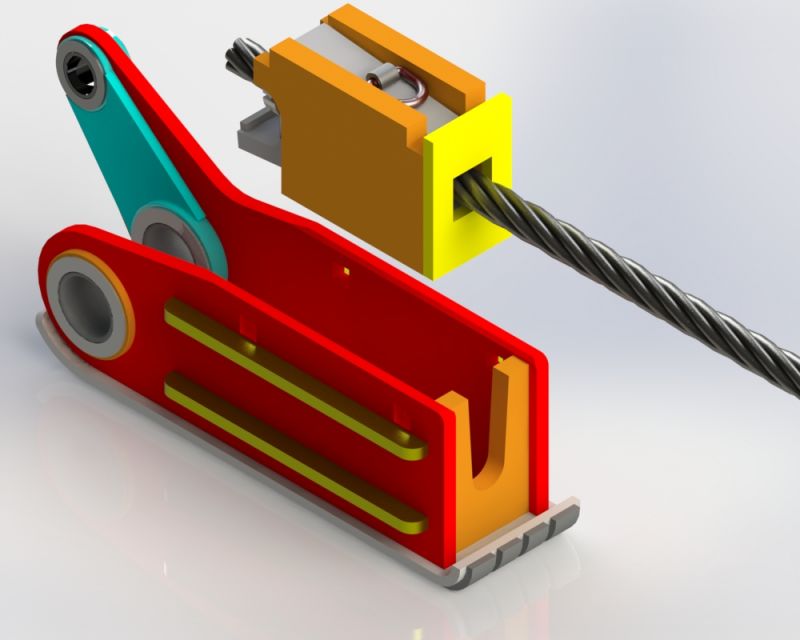

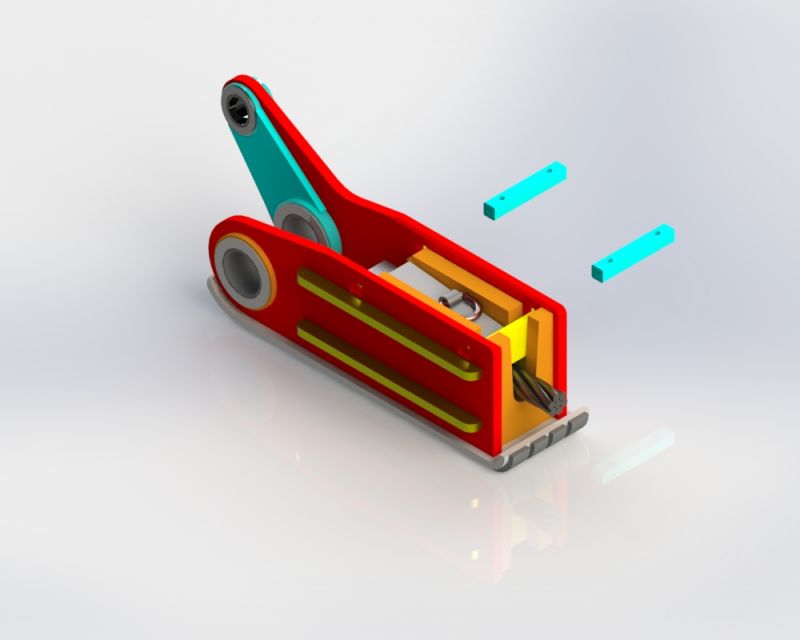

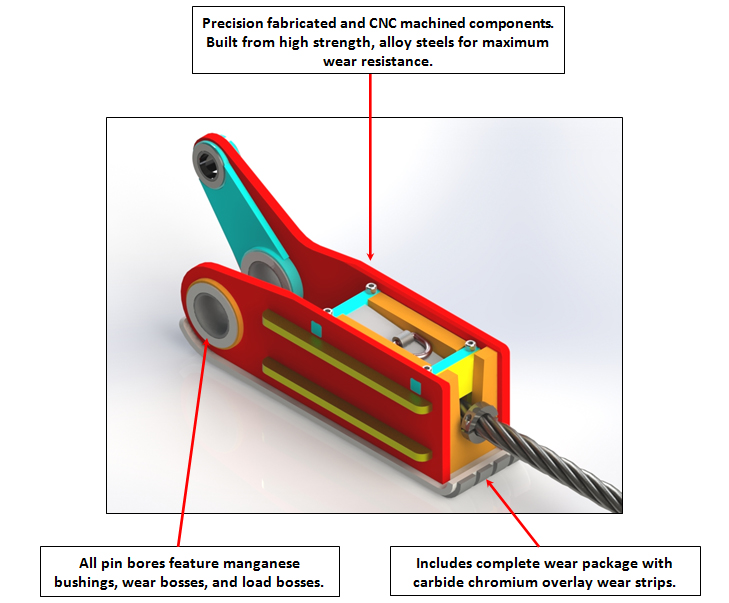

ABL ProLok Quick-Change Drag Socket

- Safer: no stored energy in rope tailout, no hammering required, no handling of heavy wedges

- Faster: fast, consistent rope changes, resocket in a fraction of the time it takes for conventional sockets

- Lighter: weighs 30%-40% less than a conventional socket & wedge

- Improved Rope Life: less rope required; no 8’-10’ tailout, shorter, lighter socket reduces rope damage/broken strands in front of socket

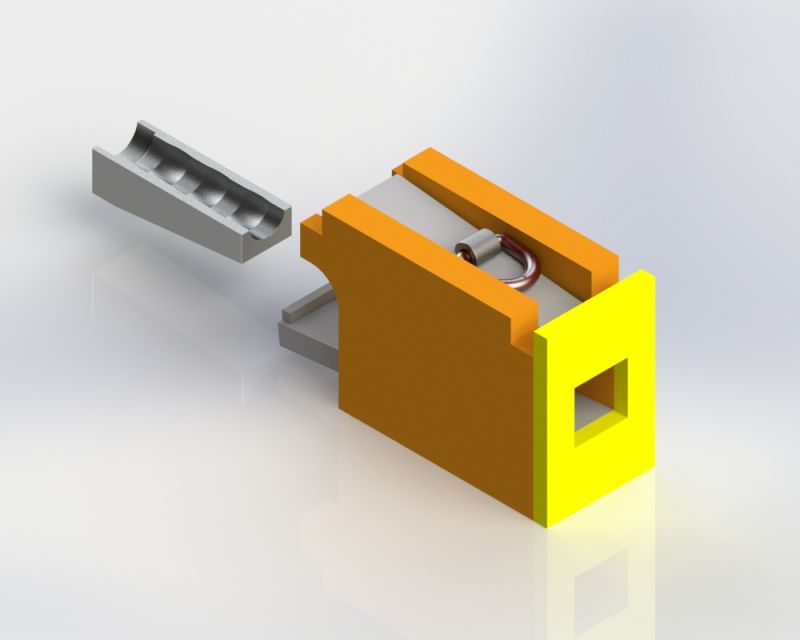

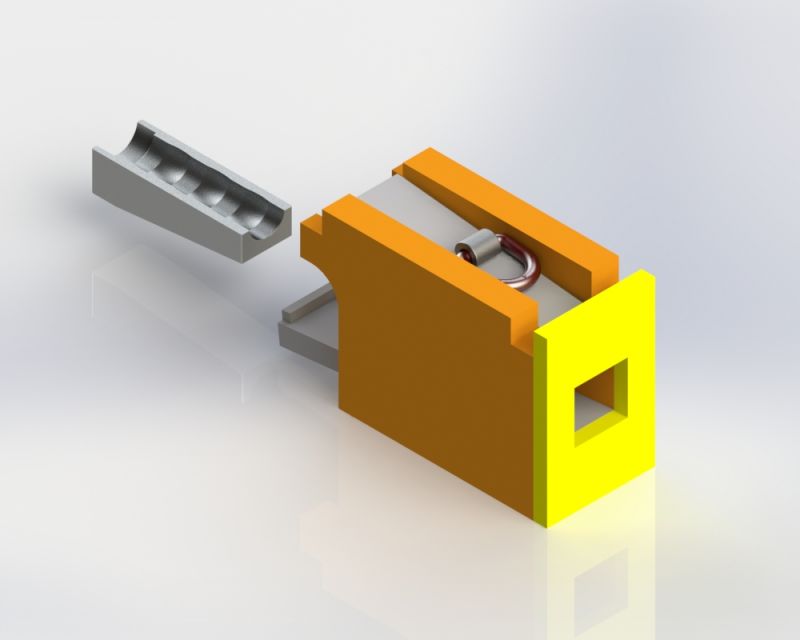

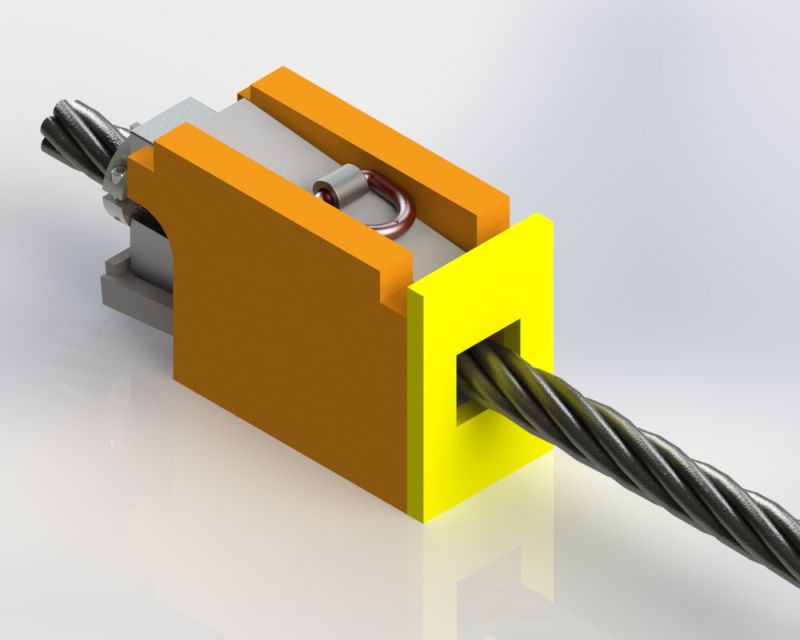

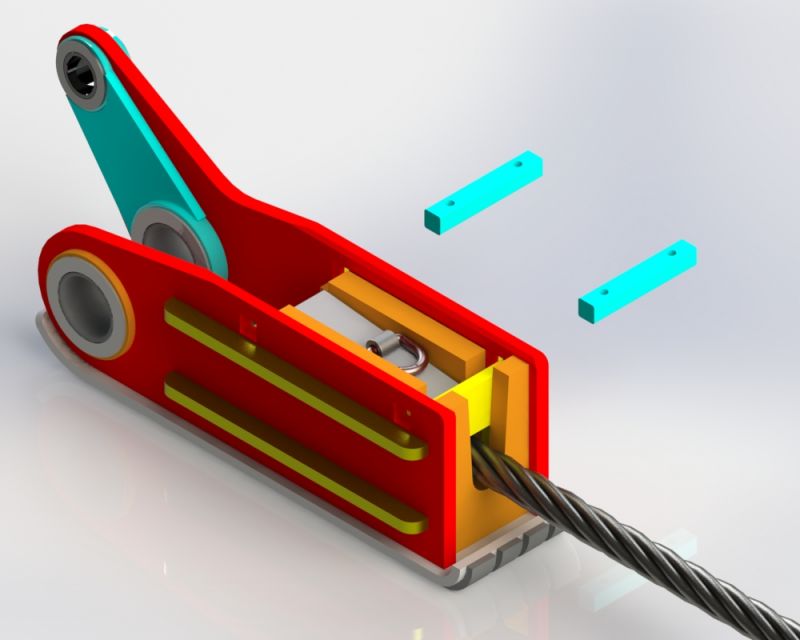

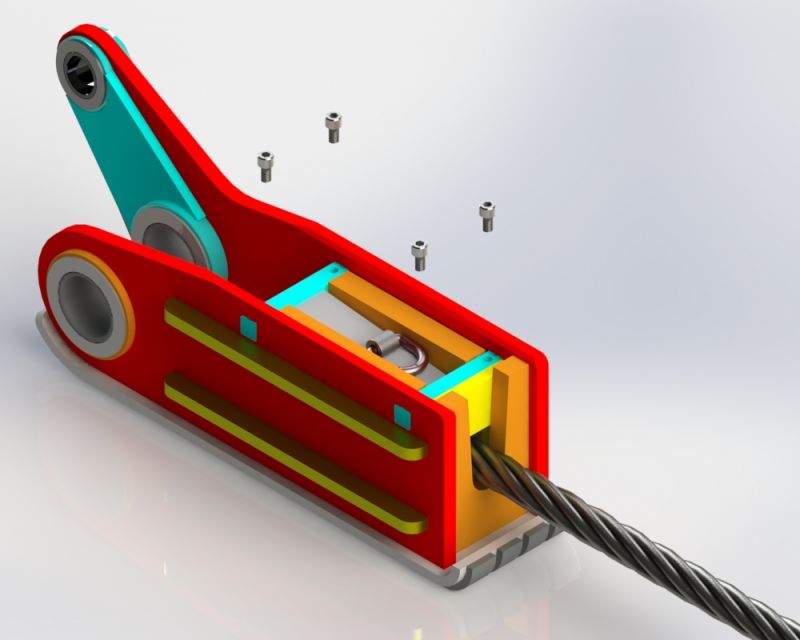

Rope Installation

|

|

|

|

|

|

|

|

|

|

|

8. Install safety ring on rope just outside of socket. |

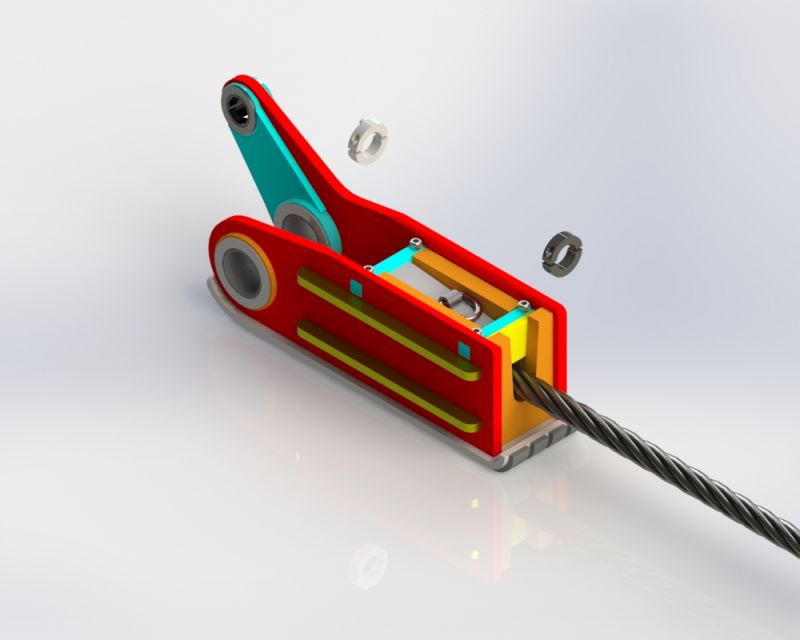

Rope Removal

|

|

|

|

|

|

|

|

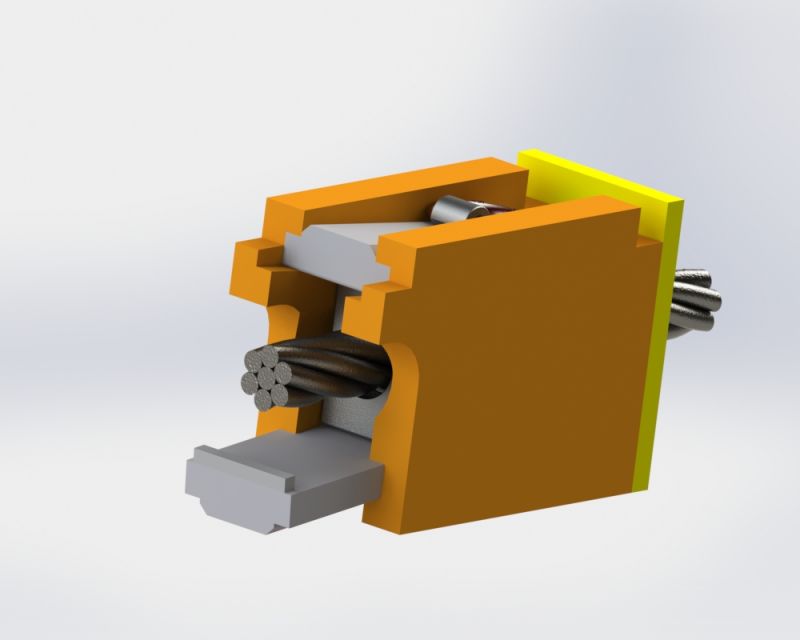

Once the used locking case is removed from the socket, it can be sent to ABL for refurbishment. On receipt, ABL will remove the trapped rope and locking wedges from the locking case. ABL will clean out the locking case, magnaflux, inspect, and make any necessary repairs to ensure the case is to specifications. The locking case will be painted and returned to the customer with a new set of locking wedges ready to install. Mine personnel will never have to remove rope from the socket. No hammering will ever be required. |