903-509-2256

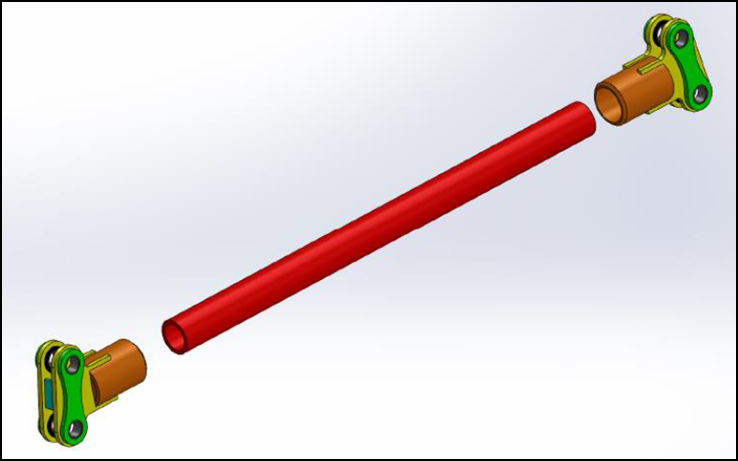

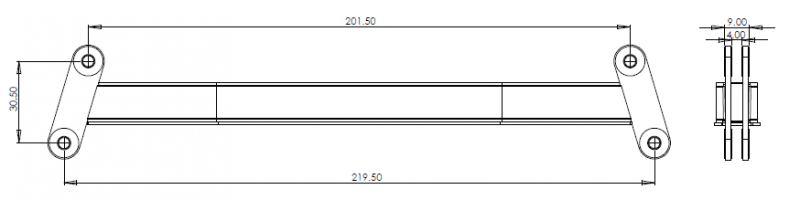

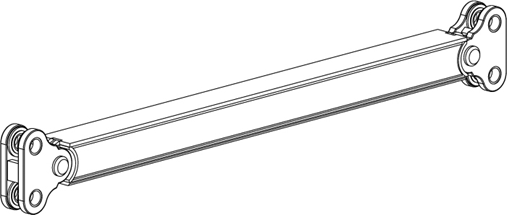

ABL Lower Spreader Bars-Hoist

- Reduced wear on pins & hoist chains

- Reduced damage to bucket

- Replaceable center section

- 2x-3x improvement in spreader bar life

- Maintenance friendly

- 1-year warranty on ends

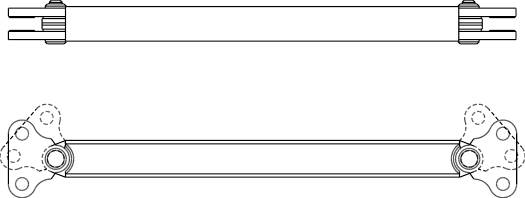

Dramatic reductions in the standard wear on pins and hoist chains is realized due to the majority of the movement transferred through the unique pivot pin. The back of the pivot end is cupped by the center section and supports the load along with the pivot pins. This increased contact area lowers the pounds per square inch in the bearing area and increases the service life.

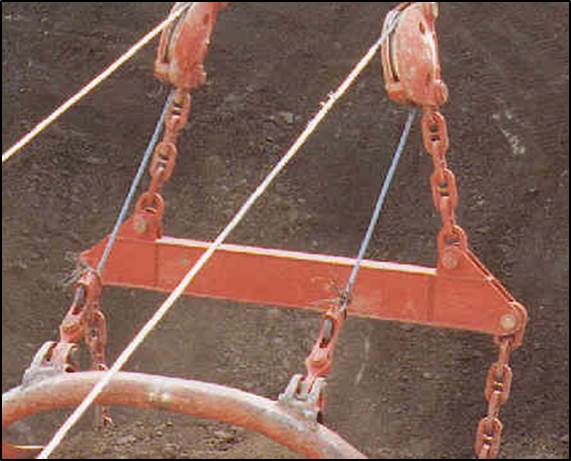

This 3-Piece design also works to reduce bucket damage. When the bucket lands, the weight goes off the hoist and the spreader ends pivot down. When the ends pivot down the center moves up at the same time. This lowers the velocity of the impact of the spreader bar center section with the bucket. The pivot also dampens the harmonic resonance from the impact, which usually cracks the ID of a pipe type spreader bar. The majority of the spreader bar damage will be in the center section where it impacts the bucket. The ABL three-piece spreader lowers maintenance costs by allowing the replacement of the center section alone. Maintenance can remove the pivot pins and install the new center while the hoist chain pins can remain attached to the pivot ends.