903-509-2256

Wear Resistant Ceramic

G 2T – WEAR RESISTANT ALUMINA CERAMIC

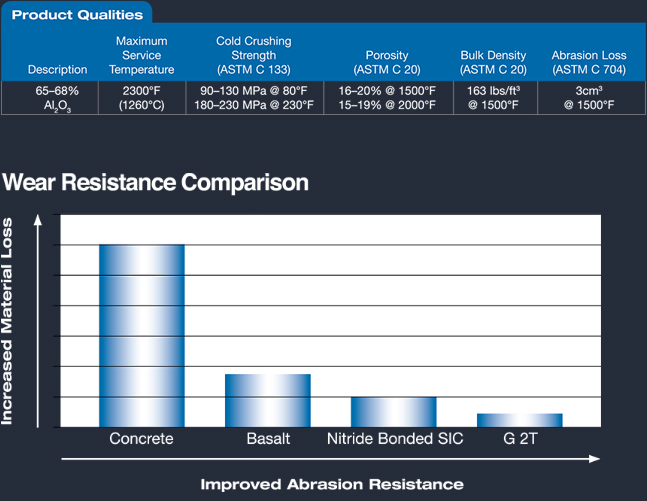

G 2T is an alumina ceramic high technology refractory, with a high abrasion and temperature resistance. G 2T is shipped unbonded in a 55lb bag. When blended with water G 2T becomes an excellent wear material for environments where weak acids and alkalis are present. It can be cast, hand packed or troweled in place. G 2T has a long working time for an easy installation. With an operating temperature range of up to 2300°F and exception abrasion resistance G 2T is an ideal material for use in cyclones, transfer lines catalysts, reactors and regenerators, refineries, transfer lines of coal and coke, wear plates, fans lining, etc.

Application

G 2T is packaged as an unbonded powder in 55lb bags. When mixed with water G 2T yields a mortar like product. The typical pallet quantity is 40 bags per pallet. Mixed G 2T can be applied by trowelling, hand packing, casting, or spraying. Steel fibers can be added to increase the structural strength of the cured product. Wire mesh is required to reinforce G 2T for most applications. The mesh serves to hold the uncured G 2T in place during application. Tools and mixing equipment can be cleaned with warm water.

Advantages

- Suited for high temp wear resistant applications

- Dense ceramic with low porosity

- Excellent consistency for troweling vertically & overhead

- Eliminates epoxy fumes and reduces welding required

- Monolithic finish eliminates tile cutting and joints

- Can be precast to eliminate air cure

- Easy To mix

G 2T Suggested Applications

INDUSTRY

- Aluminum

- Cement

- Iron & Steel

- Power Generation

- Waste Incineration

- Mining

- Kiln Curing

- Refining

- Rock Products

- Chemical

- Die-Casting

- Incineration

- Zinc Production / Casting

- Boiler Manufacturing

- Precast Manufacturing

- Mineral Processing

- O.E.M. Furnace Builders

WEAR LINING APPLICATIONS

- Transition Sections

- Elbows

- Wear Backs

- Ductwork

- Chutes

- Vibration Feed Systems

- Containent Panels

- Scrubbers

- High Wear Inlet Corners

- Waste Cyclones

- Dust Collection Systems

- Feed Chutes

- Kilns

G 2T Mixing Instructions

Preparation of G 2T requires a suitable mixer with a defined quantity of water. Mixing ratio of powder to water is critical.

- A paddle mixer or Hobbart Mixer is recommended for proper distribution of materials. In the event a small batch is being applied, a high power drill (minimum 1 h.p.) with a jiffler can be used.

- The mixer should be dry, clean, and free from any dust, oil or contaminants.

- Pour the material into the mixer, and dry blend for 1 minute.

- Add the water recommended on the bag and adjust as needed. It is recommended, if needed to add in portions of 0.5%, and wait around 1 minute before adding more water.

- Mix for 8 to 10 minutes, after you add the necessary water.

- Once the mixture is ready, the consistency should be like a smooth “peanut butter” in order to be applied on the mesh. If a ball of the material is held in the hand, it should have very little “slump”.

- The material may be applied on hexmesh grid, or standard mesh for extra support. It must be free from grease or any other contaminants.

- The mix should be well packed during the applications, and assure the material fills all the mesh so that there are no voids in the material.

- Once finished installing, the material should be cured for a period from 12 to 48 hours (at 70°F) before the material is put into service. In colder temperatures, external heating may be required.