903-509-2256

Alloy Plate Products

Alloy Plate Products - Alloy Steel and Pipe, abrasion resistant steel plates, manganese wear parts and chromium overlay plate.

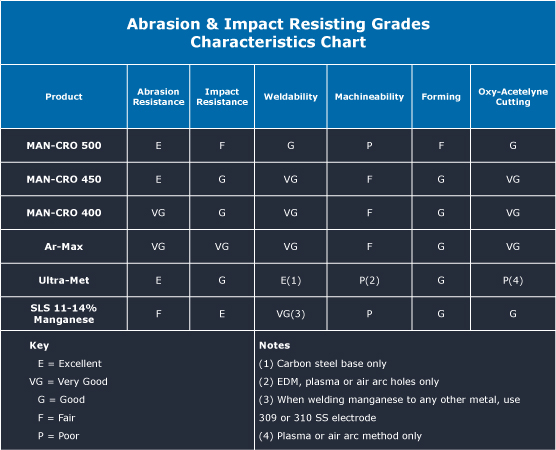

MAN-CRO®

MAN-CRO AR grades are quenched and tempered alloy steels designed to provide an excellent combination of high strength (100,000 psi minimum yield), toughness, abrasion resistance, and weldability in plate thicknesses through 3 inches. By desulphurizing and degassing during manufacture, we are able to offer a “clean” alloy while providing good cold forming characteristics and impact properties to temperatures as low as –40˚ C and still eliminate welding problems.

AR-MAX®

The Armor Plate Grade

Quality and performance guaranteed. AR-MAX® is produced to rigid specifications in electric furnaces, vacuum degassed, quenched and tempered into a unique high strength alloy steel made for a combination of ultra high strength and toughness. High Nickel content insures through hardness. AR-MAX® is designed for applications where both abrasion and/or impact resistance are major considerations.

Ultra-Met®

Ultra-Met Chromium Overlay plate is produced in our North American facility under strict process controls. The result is a surface possessing an excellent combination of high resistance to erosion, severe abrasion and moderate impact strength. With a hardness range of 550-600 BHN, Ultra-Met® is recommended for severe sliding abrasion applications.

Hardlite™

Hardlite overlay extends the range of overlay plate available from ABL. Designed for applications with weight limitations or forming requirements that can not be met by our thicker Ultra-Met™, Hardlite provides the solution. Hardlite ultra-thin chromium carbide overlay plate is available in thicknesses of 5/32˝, 13/64˝or 1/4˝ nominal. The performance of Hardlite wear plate has proven that great cost savings can be achieved compared to replacement liners/fabrications made with mild or AR steels. Hardlite Ultra-thin chromium carbide overlay plate is a composite material of ultra-hard, chromium carbide crystals.

SLS 14%®

SLS 14% Manganese Steel is one of the toughest steels available. Sometimes known as “Hadfield Manganese,” the basic composition has not changed except for the addition of small quantities of nickel and molybdenum to prevent embrittlement. Under cold work or impact its surface work hardens to three times its original state. This alloy is easily weldable and will retain its toughness at all times. All of these features, plus a tensile strength in excess of 150,000 psi, make for ideal abrasive/impact resistant service.