903-509-2256

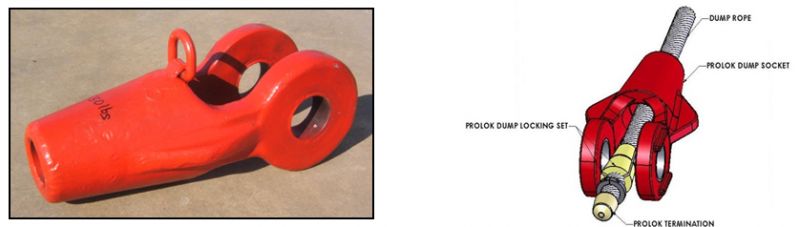

ABL ProLok Dump Rope Systems

The ProLok socket system for dragline dump ropes is a safe and proven alternative to conventional wedge style sockets. Unlike conventional wire rope sockets, the ProLok socket does not require the rope to be wrapped around a heavy steel wedge. This reduces the length of rope required for socketing and eliminates the dangerous stored energy developed by looping the rope around a conventional rope wedge. In addition, the ProLok sockets typically weigh less than half of their conventional counterparts. The reduced weight of the sockets has been proven to extend rope life and reduce the overall suspended weight of bucket rigging. Dramatic improvements in dump rope life and rope change time are consistently observed.

With ABL's ProLok dump rope socket system, maintenance personnel will never have to hammer out a steel wedge and remove rope from a socket. When it comes time to change dump ropes, simply cut the dump rope and unpin the ProLok dump sockets. ABL supplies a new, pre-cut dump rope with ProLok sockets ready to pin up.

- Immediate savings in weight and cost

- Typical rope lengths are reduced (approx. 20% reductions); No tailout necessary. Less rope means less cost & less weight.

- Sockets are dramatically reduced in size & weight; less unproductive static weight carried by the bucket. ProLok dump sockets typically weigh half or less than a conventional socket & wedge.

- Dump ropes would be supplied cut to length with pre-installed terminations & pulling loops. Less rope handling and quick initial installation mean saved time and saved time is saved money.

- Increased Production

- More run time between rope changes because the ABL ProLok sockets extend rope life.

- More run time by decreasing the time and effort required to change dump ropes.

- Safety

- Lighter weight, eliminates the need of specialty machinery and handling of heavy components.

- No hammering required to remove sockets.

- Warranty

- The “Best in Industry” warranty, full 1 year

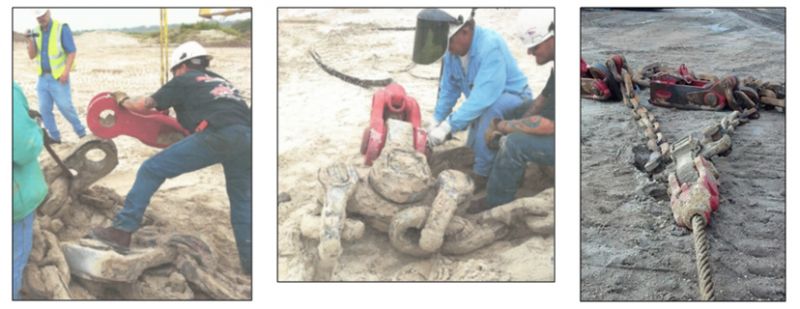

Dump ropes are delivered to the mine socketed on one end, ready to pin-up. A separate socket is provided for the other end of the rope which can be installed in the field once the dump rope is feed thru the dump sheave. Ropes are supplied cut to length with pre-installed terminations & pulling loops.

Field Installation Procedures

1. Pin the factory attached ProLok socket to the arch anchor link.

2. Pull the un-socketed end of dump rope thru the dump sheave.

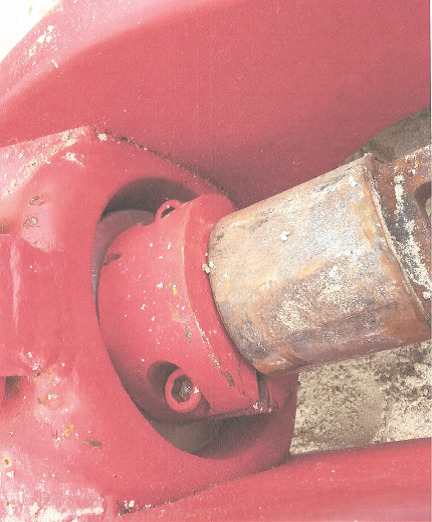

3. Insert the loose end of the dump rope into the other ProLok dump socket and pull thru socket.

4. Attach the aluminum ProLok locking wedges & load ring to the dump rope.

5. Pull the completed ProLok socket assembly to ensure seating of the locking wedges.

6. Pin the ProLok dump socket to the connecting link on the dump equalizer or drag socket depending on the application. The installation process is complete and ready to dig.

Re-Socketing

When it is time to change dump rope, cut dump rope at the sockets and remove the sockets. Replacement rope & sockets can then be installed.

Return the used sockets to ABL where the locking parts can be removed from the sockets. ABL will then clean, inspect, magnaflux, and repair the sockets. The refurbished sockets will then be returned to the mine with new rope installed, ready for installation on the dragline rigging.