903-509-2256

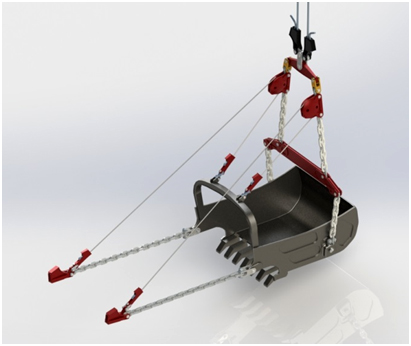

ABL Dragline Bucket Rigging Systems Overview

ABL manufactures complete, rope-to-rope, dragline bucket rigging systems for draglines of all sizes. Each engineered rigging package is custom tailored to the customer's specific application and digging conditions. ABL's rigging philosophy is based on a "race car" mentality wherein the goal is to design the lightest weight, longest lasting components that yield the greatest production with the least maintenance downtime.

ABL manufactures complete, rope-to-rope, dragline bucket rigging systems for draglines of all sizes. Each engineered rigging package is custom tailored to the customer's specific application and digging conditions. ABL's rigging philosophy is based on a "race car" mentality wherein the goal is to design the lightest weight, longest lasting components that yield the greatest production with the least maintenance downtime.

With rigging systems comprised of mostly fabricated parts, ABL has the engineering freedom to custom design rigging packages based on the customer's needs. ABL does not prescribe to the "one-style" fits all mentality of rigging design. ABL leads the industry in innovation and value added solutions for dragline bucket rigging.

Customers running ABL rigging packages routinely get (12) months or more run time with no maintenance or lubrication. In addition, ABL can provide a complete rigging package in as little as (8) weeks from receipt of order.

All of ABL's rigging systems feature the same core features:

- Custom engineered

- Quality engineering: fitment & compatibility

- Precision manufacturing

- Extensive quality control

- High strength, alloy materials

- Hard face wear bosses & load bosses

- Proprietary metallurgy & heat treating

- High lubricity, manganese bushings

- Integrated function components

- Fewer pieces, standardized pin sizes

- Wear resistant overlay where required

- No lubrication required, factory sealed dump blocks

- Light weight, long lasting parts

- Quick lead times, fast turnaround

- ABL Dragline Rigging Warranty